CANNING

-

FILL FIZZ (CSD FILLER)

-

FILL HOT JUICE (JUICE FILLER)

-

FILL STILL (WATER FILLER)

-

FILL GLASS (GLASS FILLER)

-

WASHERS GLASS

-

FILL VISCUOS

-

20 LITER JAR

-

CANNING (CAN FILLER)

-

LABEL HOTGLUE

-

LABEL SHRINK SLEEVE

-

PSL LABELER MULTIHEAD

-

LABEL STICKER (PSL)

-

CUT LABEL HOTGLUE

-

FUZEPACK

-

PACKERS

-

CONVEYORS

-

CASE OVER PACK(COP)

-

ROBOT

-

AUTOMATION & SPM’s

-

PROCESS EQUIPMENT

-

Mix BEVMIX

-

Mix MIXOMATIC

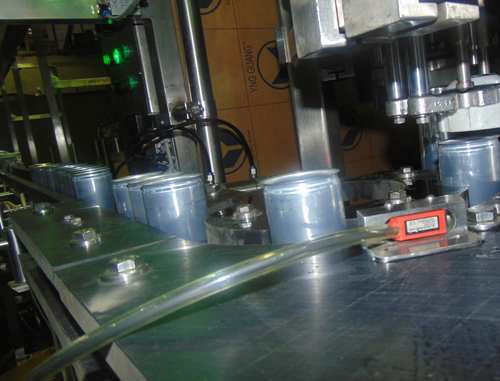

CANNING

- Filling Valve for the Can Positively by double rod can via centring bell canters the Can top Mouth thus never Cans will be damaged and this will also give high filling level accuracy

- TilterRinser turns can from 0-180 then Rinsing & then 180 back to 0 degree thus ensuring smooth can handling

- Can seamer Rollers made with high accuracy profile to form perfect seam on the can with the LID

- Can Seamer Rollers made with high Quality material very specialized for long life and thus the roller profiles are maintained thus the double seam accuracy too is maintained

- Seaming can & Lid features and troubleshooting available at site www.doubleseam.com

- Machine has Filler and seamer on Single Frame

- Filler has specially designed rotary to stationary Stuffing box and 100% Capable to do CIP capable to supply Product + Compressed airto Rotary annular tank.

Canning lines from Hilden are built by superior technology and capable of handling a variety of products from carbonated products or Energy Drinks or Still beverages or any other Liquid product to be packed. A complete line consists of de-palletizers or turn tables, fillers, seaming, warmers, coders, shrink packers and palletizers.

Cans received on a pallet are unwrapped and automatically conveyed to the de-palletisation station from where layer by layer are swept by an arm onto a conveyor from where they are marshalled to a single file. A vacuum arm lifts off the inter layer cardboard partition sheets and stacks them in a magazine for recycling. In the high level depalletizer, as each layer is swept off the remaining stack of can rises the height of one can. Optionally for slower lines, cans are manually placed on the turntable and smoothly transferred to the conveyor and on to the rinser.

In the rinser, cans assisted by gravity are guided by a spiral for inversion, where they are then rinsed and re-inverted for filling. Rinsing has three sections, re-circulated jetting, fresh water jetting and finally sterile air blow to eliminate droplets.

In higher speed fillers the cans in a single line are pitched out by a feed worm, into the star wheel and to the filler, where depending on the product; the suitable filling valve is used. In lower capacity machines the cans are fed directly into the infeed star wheel of the filler. Once on the filling platform, a positively lifted centering device centers and seals the can. After filling the can is conveyed through to the seamer , which is mechanically synchronized with the filler, by a gear train.

Lids stacked in the can lid chute are individually separated and transferred to the can mouth in perfect synchronization. A no can, no lid pneumatic safety system prevents lid wastage. The can is raised, stabilized by a top load roller, before the primary and secondary roller engage for forming and sealing of the lid and can. The specially profiled high speed

| CANNING LINE | |||

|---|---|---|---|

| NO. | Specification | ||

| 1 | NO OF FILLING HEADS | 12 / 16 / 20 / 24 / 30 / 40 | |

| 2 | NO OF SEAMING HEADS | 4 / 4 / 8 / 10 / 12 / 15 | |

| 3 | SPEED OF MACHINE | FROM 60 TO 300 Cans Per Minutes | |

| 4 | CAN SIZES CAPABLE | 250 / 330 & 500 ML cans | |

| 5 | MODELS FILLER / SEAMER | 12/4 - 16/4 - 20/4 - 24/8 - 30/12 - 40/15 | |

| 6 | TYPE OF CANS | ROUND | |

| 7 | OPERATING HIEGHT | 1150 MM | |

| 8 | FILLING VALVE FEATURE | CAN IS POSITIVELY CENTERED BY MOUTH | |

| 9 | JETTING | HOT, COLD, CHEMICAL AND OR COMBINATION | |

Contact us

- Santosh Engineering Works

- Address:

Gala No. 5 & 6 , SR.No.36/14 Valaram Ashish Ind.Estate, Dhumal Nagar, Waliv Vasai (E) Palghar Maharashtra - 401202

- Phone: +91 7219594979 / +91 8329208105

- Phone: +91 9930315769 / 8169233981

- E-mail: info@santoshengg.com

- E-mail: santoshengineering13041975@gmail.com