FILL-HOT JUICE (JUICE FILLER)

FILL FIZZ (CSD FILLER)

FILL HOT JUICE (JUICE FILLER)

FILL STILL (WATER FILLER)

FILL GLASS (GLASS FILLER)

WASHERS GLASS

FILL VISCUOS

20 LITER JAR

CANNING (CAN FILLER)

LABEL HOTGLUE

LABEL SHRINK SLEEVE

PSL LABELER MULTIHEAD

LABEL STICKER (PSL)

CUT LABEL HOTGLUE

FUZEPACK

PACKERS

CONVEYORS

CASE OVER PACK(COP)

ROBOT

AUTOMATION & SPM’s

PROCESS EQUIPMENT

Mix BEVMIX

Mix MIXOMATIC

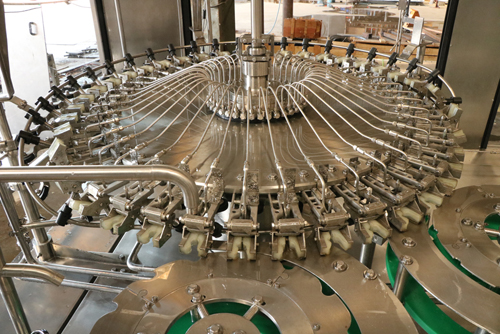

FILL-HOT JUICE (JUICE FILLER)

- Intelligent Machine PLC control with Colour touch Screen 7.5/12.5 Inch for Data logging.

- Introducing 2 new types of re-circulation valves, one through the valve bottom close design and the other through the tank. Both are extremely hygienic designs.

- This filler can fill any pulp products at temperature from 70 to 95 degrees centigrade.

- All Machine moving parts Like Rinser Bracket/Lift cylinder handling, are Water Lubricated.

- UP / DOWN State of the art easily open able guards with all inter locking safeties.

- Interactive intelligence by means of a huge TFT Colour touch screen with all necessary alerts via real time clock & Trouble shooting

- Bottles are handled by means of neck with extremely accurate transfer system, with no scuffing even at high speeds.

- State of the art latest design cap elevator cum orientor system, eleminating blowers, eliminating cap contamination.

| NO. | 2000 ml | FILL-HOT JUICE | |||||

|---|---|---|---|---|---|---|---|

| R/F/C | 250 ml | 500 ml | 1200 ml | 2000 ml | |||

| BPM | BPM | BPM | BPM | ||||

| 1 | 9/9/4 | 40 | 25 | 10 | 5 | ||

| 2 | 10/10/4 | 60 | 35 | 15 | 8 | ||

| 3 | 12/12/4 | 70 | 45 | 20 | 10 | ||

| 4 | 16/16/6 | 90 | 65 | 30 | 15 | ||

| 5 | 20/20/6 | 120 | 80 | 40 | 20 | ||

| 6 | 24/24/8 | 140 | 95 | 50 | 25 | ||

| 7 | 24/30/8 | 180 | 120 | 60 | 30 | ||

| 8 | 30/30/10 | 200 | 135 | 65 | 32 | ||

| 9 | 35/35/10 | 210 | 145 | 70 | 35 | ||

| 10 | 40/40/10 | 240 | 160 | 80 | 40 | ||

| 11 | 40/50/12 | 300 | 200 | 100 | 50 | ||

| 12 | 40/60/14 | 350 | 250 | 120 | 65 | ||

Inside of bottles are rinsed by spraying water or air or both. Empty bottles are transferred into the rotary rinsing section by an inlet neck guide. The bottles are held from their neck and inverted by a guide rod along their axis. After being sprayed internally, the bottles continue to move inverted for a while to drain the rinse water, after which they are turned back to the upright position. The nozzles have ”No Bottle - No Spray System” which is activated only by the presence of bottles, sensed at the in feed spider. The option of attachment of a independent rinser machine is possible, to build a Mono Bloc Machine of Rinser filler crowner/capper for Glass bottles.

The filling operation is by gravity. RECIRCULATING VALVE (mechanical valve) which features 10-15 % juice recirculation from each valve for maintaining the filling bowl juice temperature upto the tip of the filling valve constant, hence maintaining product safety without any manual intervention. This valve has a bottom close design and has a zero drip feature after the fillingopertation, it has CIP features & fills at a very high speed due to its excellent design.

The other option of the valve is a top close straight valve with recirculating from the filler bowl by means of a pump this is also a efficient cost saving design. An option of Flow meter along with a pneumatic actuator valve (electronic filling valve) for extremely accurate fill can in now available.

Different capping heads can be installed on the monoblock machine to apply plastic screw caps, aluminum caps and metal crown corks. Two types of caps can be applied on the same machine in order to have capability to apply different closures.

Contact us

- Santosh Engineering Works

- Address:

Gala No. 5 & 6 , SR.No.36/14 Valaram Ashish Ind.Estate, Dhumal Nagar, Waliv Vasai (E) Palghar Maharashtra - 401202

- Phone: +91 7219594979 / +91 8329208105

- Phone: +91 9930315769 / 8169233981

- E-mail: info@santoshengg.com

- E-mail: santoshengineering13041975@gmail.com