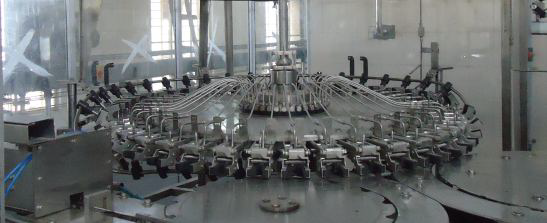

FILL-VISCUOS

FILL FIZZ (CSD FILLER)

FILL HOT JUICE (JUICE FILLER)

FILL STILL (WATER FILLER)

FILL GLASS (GLASS FILLER)

WASHERS GLASS

FILL VISCUOS

20 LITER JAR

CANNING (CAN FILLER)

LABEL HOTGLUE

LABEL SHRINK SLEEVE

PSL LABELER MULTIHEAD

LABEL STICKER (PSL)

CUT LABEL HOTGLUE

FUZEPACK

PACKERS

CONVEYORS

CASE OVER PACK(COP)

ROBOT

AUTOMATION & SPM’s

PROCESS EQUIPMENT

Mix BEVMIX

Mix MIXOMATIC

FILL-VISCUOS

- Intelligent Machine PLC control with Colour touch Screen 7.5/12.5 Inch for Data logging.

- Positive Piston type filling valve for accurate dozing of the product. Open/closing of the valve is by means of a pneumatic actuated striker, ensures ‘no bottle no fill’.

- The Positive Piston type valve can be manufactured in various sizes depending on the maximum bottle size. The piston dose roller cam can easily be adjusted by means of a hand wheel or it could be servo controlled to achieve accurate fill height. All the wear parts are of Teflon, Viton, Silicone, EPDM only, for very long life.

- All Machine moving parts Like Rinser Bracket/Lift cylinder handling the PET Bottle neck Run are Water Lubricated.

- Sliding UP / DOWN State of the art open able guards with all safeties are provided as an option.

- Interactive intelligence by means of a huge TFT Colour touch screen with all necessary alerts via real time clock & trouble shooting information.

- Bottles are handled by means of neck/body guides with extremely accurate transfer system and no bottle scuffing even at high speeds.

- State of the art latest design cap elevator cum orientor/vibro hopper feeding through a chute on to the bottle.

| NO. | FILL-STILL WATER | Model | |

|---|---|---|---|

| POSITIVE PISTON VALVES WITH SPEEDS FROM 30-300 BPM FOR : | |||

| NO. | Specification | ||

| 1 | KETCHUP | 9/9/4 | |

| 2 | THICK SHAKES | 10/10/4 | |

| 3 | YOGURT | 12/12/4 | |

| 4 | SHAMPOO | 16/16/4 | |

| 5 | COUGH SYRUPS FOR PHARMACEUTICAL | 18/18/6 | |

| 6 | EDIBLE OIL | 20/20/6 | |

| 7 | LUB. OIL | 24/24/8 | |

| 8 | JAMS/JELLY | 24/30/8 | |

| 9 | SQUASHES | 30/30/10 | |

| 10 | OR ANY OTHER VISCOUS FOOD PRODUCTS | 40/40/10 | |

| 30/50/12 | |||

| 40/60/12 | |||

| 60/80/20 | |||

Inside of bottles are rinsed by spraying water or air or both in the rinsing section. Empty bottles are transferred into the rotary rinsing section by an inlet neck guide. The bottles are held by their neck and turned upside down by grippers along their axis. After spraying operation, the bottles continue to move inverted for a while, to drain the rinsing water and then reinverted to the upright position. The nozzles have”No Bottle - No Spray System” activated only by the presence of bottles, by means of an infeed sensor.

The filling operation is carried out by means of POSITIVE PISTON type valve.The Positive Piston valve can be made in difeerent sizes depending on the size of the bottles to be handled. The principle of filling is similar to an injection where the piston rises on a cam to suck liquid from the main tank to the required volume and then dosed in to the bottle.There is the possibility of precision setting. A second option is servo based filling. These valves are completely made by CNC machines.

Different capping heads can be installed on the monoblock machine to apply plastic screw caps, aluminum caps, metal crown corks etc. Two different types of capping heads can be installed on the same monoblock upon request in order to have the flexibility to apply different closures on the same machine.

Contact us

- Santosh Engineering Works

- Address:

Gala No. 5 & 6 , SR.No.36/14 Valaram Ashish Ind.Estate, Dhumal Nagar, Waliv Vasai (E) Palghar Maharashtra - 401202

- Phone: +91 7219594979 / +91 8329208105

- Phone: +91 9930315769 / 8169233981

- E-mail: info@santoshengg.com

- E-mail: santoshengineering13041975@gmail.com